Electrostatic Glossy Smooth Powder Coating Polyester Resin Lead Free RAL 1018

-

High Light

RAL 1018 Powder Coating Polyester Resin

,Lead Free Powder Coating Polyester Resin

,Glossy Smooth Electrostatic Powder Coating

-

RAL1018

-

ColorPoLyster White

-

MethodSpray

-

Surface TypeCustomized

-

Gloss Range86-100%

-

Particle Size32 - 42um

-

Application MethodSpray,electrostatic Spraying

-

StatePowder Coating

-

UsageAppliance Paint

-

Main Raw MaterialEpoxy&Polyester

-

MfPowder Coating Paint

-

Cas No.Powder Coating Powder

-

GlossHigh Gloss/semi-gloss/matt

-

Product NameEpoxy Polyester Powder Coating

-

AppearanceFine Powder,smooth Powder

-

Shelf Life24 Months At ≤35℃

-

FeatureEco-friendly,Leveling,long-lasting,Long Lasting

-

SurfaceSmooth And Texture,Gloss,matte,texture,Hard

-

Place of OriginChina

-

Brand NameFeihong

-

CertificationCE, ROHS, BV, TUV

-

Model NumberRAL1018

-

Minimum Order QuantityNegotiable

-

PriceNegotiable

-

Packaging DetailsTwo-ply PVC bag inside with carton box

-

Delivery Time7 days

-

Payment TermsL/C, T/T, Western Union, MoneyGram

-

Supply Ability400 T/Month

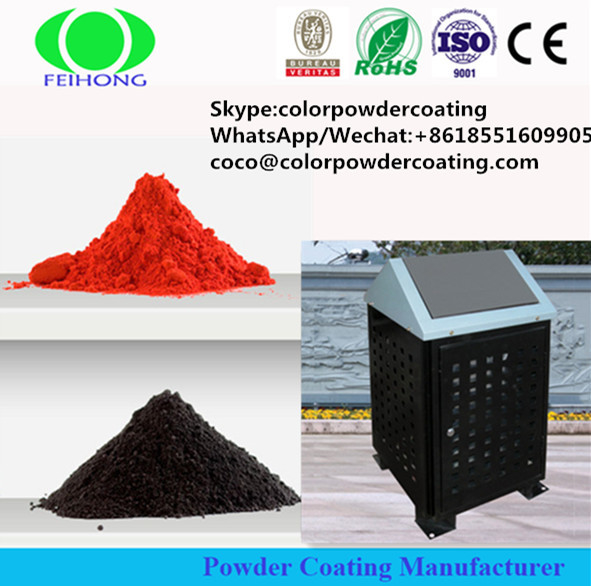

Electrostatic Glossy Smooth Powder Coating Polyester Resin Lead Free RAL 1018

electrostatic powder coating glossy smooth yellow RAL 1018 lead free powder coating polyester resin

GLOSSY DURABLE POLYESTER POWDER COATING ( FH-GP Series )

INTRODUCTION

FH-GP Series is a thermoset powder coating based on saturated polyester resins specially selected for exterior use. It is formulated to give properties of good flow-out and satin or glossy finish. Its outstanding resistance to ultra-violet light and atmospheric aging make it highly decorative and durable in outdoor environment,It is widely used for outdoor furniture,architectural hardware,air-conditioners,bicycle frames,garage doors and signboards etc .

GLOSS AND COLOR RANGE

Gloss levels range from 50- 90% and above

A wide range colors are available ,certain color is subject to the technical approval .

APPLICATION SCHEDULE

Applied by electrostatic spraying gun that can provide negative tension of 60-80 kV.

Curing schedule :10 minutes at 200℃ (metal temperature )

Optimal film thickness : 60 - 80 um POWDER PROPERTIES Specific gravity : 1.25 - 1.75 (depend on colors)

Particle size distribution(Laser Particle size analyser) :Less than 5% above 100 um 50 – 65% above 32 um : Average particle size : 35- 45um

COATING PROPERTIES

The following are typical properties determined on 0.8 mm gauge degreased galvanised steel

Film thickness (ISO 2178) : 60 - 80 µm

Flow out : Good Gloss (ISO 2813, 60º) : >50 %

Adhesion (ISO 2409) : GT= 0

Pencil hardness(ASTM D3363 ) : H – 2H

Direct and reverse impact (ASTM D2794) : 50kg.cm

Salt spray Resistance ( ASTM B117, 1000hrs) (Maximum undercutting ,1 mm ): No blistering

Humidity Resistance (ASTM D2247,1000 hrs): No blistering or loss of adhesion

Chemical Resistance : Film unchanged (48 hours contact with the coating at ambient temperature) (Hydrochloric acid 10%,Hydrogen sulphide (saturated),Hydrogen peroxide 40 vol,Ammonium hydroxide 33%,Sodium hydroxide5%,Tartaric acid 5%,Citric acid 5%, Lactic acid 5%, Ethanol, n-Butanol)

SUBSTRATES AND PRE-TREATMENT

In order to obtain optimal anti-corrosion properties, it is recommended to apply a chemical pretreatment prior to powder coating application.

Ferrous metals(cold rolled steel, cast iron etc.): Iron or zinc phosphatation

Zinc surfaces(galvanized steel, zinc alloy) : Chromatation or zinc phosphatation

Aluminum alloys : Chromatation STORAGE Under dry conditions ,good ventilation at a temperature not exceeding 25 C,humidity < 60%.

Storage period recommended should not exceed 6 months,in case exceeding 6 months without affecting their free flowing properties, the powder will still have optimal characteristics.

Should be protected from excessive heat,humidity,water and contamination with foreign materials such as powder, dust, dirt, etc.

Any leftover powder should be kept in an appropriate area that is cool and dry. Do not expose to the air too long as the powder properties may deteriorate with the moisture

![]()

![]()

![]()

![]()

![]()