Electrostatic Thermoset Architectural Powder Coatings , RAL1024 Heat Proof Powder Coating

-

High Light

fluidized bed powder coating

,automotive powder coating

-

ColorOchre Yellow

-

RALR1024

-

Gloss74%

-

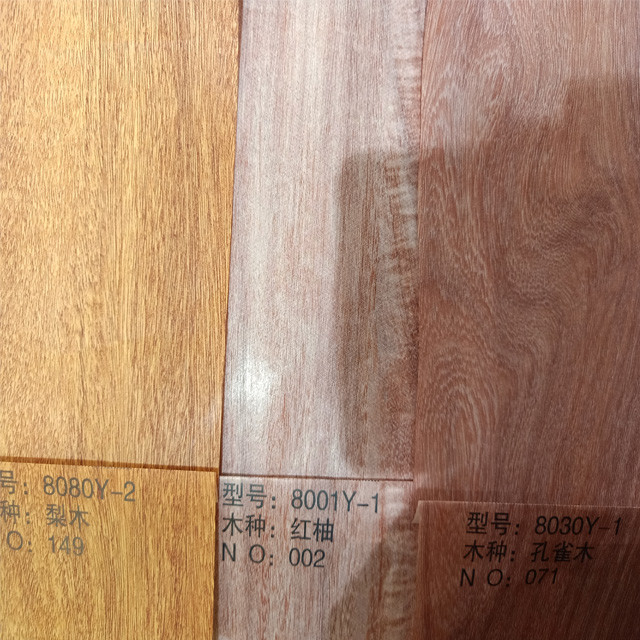

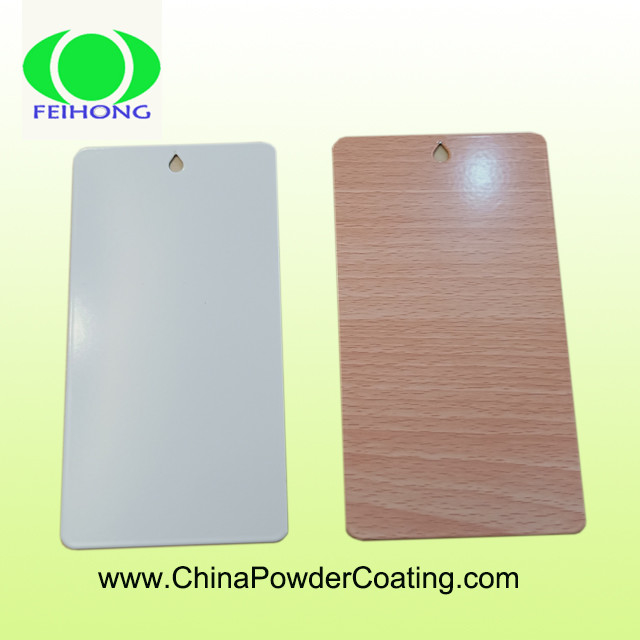

AppearanceWood Grain

-

Impact50kg

-

Salt Resistant1000Hours

-

Place of OriginChina

-

Brand NameFEIHONG TOPO

-

CertificationCE, SGS, BV, ISO

-

Model NumberTPC-RAL1024

-

Minimum Order QuantityNegotiable

-

PriceNegotiable

-

Packaging DetailsTwo-ply PVC bag inside with carton box

-

Delivery Time7 days

-

Payment TermsWestern Union, MoneyGram, L/C, T/T

-

Supply Ability400ton/Month

Electrostatic Thermoset Architectural Powder Coatings , RAL1024 Heat Proof Powder Coating

Electrostatic Thermoset Architectural Powder Coatings , RAL1024 Heat Proof Powder Coating

While powder coatings have many advantages over other coating processes, there are limitations to the technology. While it is relatively easy to apply thick coatings which have smooth, texture-free surfaces, it is not as easy to apply smooth thin films. As the film thickness is reduced, the film becomes more and more orange peeled in texture due to the particle size and TG (glass transition temperature) of the powder.

For optimum material handling and ease of application, most powder coatings have a particle size in the range of 30 to 50 μm and a TG > 40°C. For such powder coatings, film build-ups of greater than 50 μm may be required to obtain an acceptably smooth film. The surface texture which is considered desirable or acceptable depends on the end product. Many manufacturers actually prefer to have a certain degree of orange peel since it helps to hide metal defects that have occurred during manufacture, and the resulting coating is less prone to show fingerprints.

There are very specialized operations where powder coatings of less than 30 micrometres or with a TG < 40°C are used in order to produce smooth thin films.

Powder coatings have a major advantage in that the overspray can be recycled. However, if multiple colors are being sprayed in a single spray booth, this may limit the ability to recycle the overspray.

Suit your widest needs

-

Home appliances.

-

Automotive parts.

-

Bicycle components.

-

Coating of aluminum extrusions.

-

Window frame.

-

Wind powers.

-

Agricultural equipment.

-

Aerospace areas.

-

Interior and exterior furniture.

-

Architecture construction.

-

Metal fence and rails.

-

Food service areas.

-

Goods display, etc.

-

All kinds of Machines

There are two main categories of powder coatings: Thermosets and thermoplastics. The thermosetting variety incorporates a cross-linker into the formulation. When the powder is baked, it reacts with other chemical groups in the powder polymer and increases the molecular weight and improves the performance properties. The thermoplastic variety does not undergo any additional reactions during the baking process, but rather only flows out into the final coating.

The most common polymers used are polyester, polyester-epoxy (known as hybrid), straight epoxy (Fusion bonded epoxy) and acrylics.

| Testing Items | Standard | Data |

| Appearance | Flat And Smooth | |

| Coating Thickness | GB/T6554-2003 | 50~70mm |

| Gloss(60°) | GB/T9754-2007 | From 2%~100% to All Gloss |

| Impact Resistance | GB/T1732-1993 | 50kg.cm |

| Bending Performance | GB/T6742-2007 | 2mm |

| Cupping | GB/T9753-2007 | 8mm |

| Adhesion Force | GB/T9286-1998 | 0 Grade |

| Hardness | GB/T6739-2006 | 2H |

|

Resistant to Salt (1000 Hours) |

GB/T1771-2007 | No Change For Coating Appearance |

| Humidity And Heat Resistance (1000 Hours) | GB/T1740-2007 | No Change For Coating Appearance |

|

Chemical Medium Resistance (240 Hours) 5%H2SO4 5%HCl 5%NaOH 5%NaCl |

GB/T1763-1979 |

No Change For Coating Appearance No Change For Coating Appearance No Change For Coating Appearance No Change For Coating Appearance |

| Heat Resistance | GB/T1735-2009 | It Can Reach Between 220℃/20minutes And 240℃/40minutes According To Color And Different Requirement |

![]()

![]()