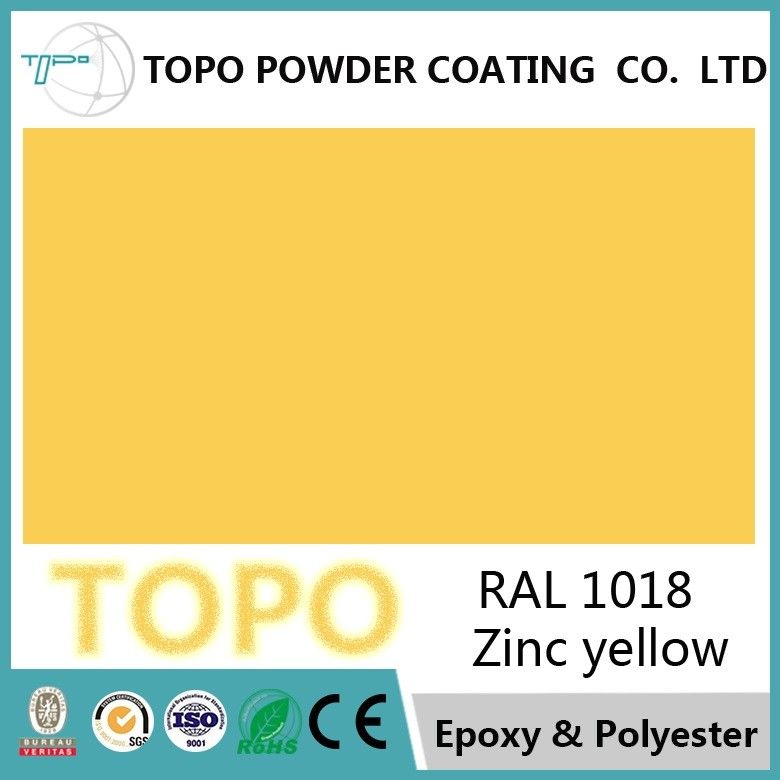

RAL 1018 Pure Polyester Powder Coating For Household Electry Appliance

-

High Light

polyester powder coating paint

,uv resistant powder coating

-

RAL1018

-

ColorZinc Yellow

-

AppearanceFine Powder

-

Acid Resistance10% CH3COOH, 240 Hours

-

Alkali Resistance10% NaOH, 240 Hours

-

UvioresistantQUV-313,500 Hours

-

Place of OriginUkraine

-

Brand NameTOPO

-

CertificationCE, ROHS, BV

-

Model NumberRAL1018

-

Minimum Order QuantityNegotiable

-

PriceNegotiable

-

Packaging DetailsTwo-ply PVC bag inside with carton box

-

Delivery Time7 days

-

Payment TermsL/C, T/T, Western Union, MoneyGram

-

Supply Ability400 T/Month

RAL 1018 Pure Polyester Powder Coating For Household Electry Appliance

RAL1018 Zinc yellow Pure polyester Powder Coating Paint for Household Electry Appliance

Pure polyester powder coating starts as granules of industrial polyester. The granules are mixed with coloring agents and chemicals and then fed into an extruder where the mixture is heated until it melts together. The extruder pushes out the mixed material where it is rolled flat and allowed to dry. The dry sheets are broken into chips and then ground into powder.

A thermoset coating undergoes a chemical reaction when heated, making the coating stronger than its constituent parts. A thermoplastic coating simply melts together during the curing process. While thermoplastic coverings are not as strong as thermoset, they are stronger than most conventional wet coverings.

1). No intoxication, no fire, no "three wastes" emissions and no other pollution problems

2). Raw material utilization is high, more than 99%.

3). Easy to automate operation, high production efficiency to reduce costs.

4). High coverage corners, with excellent resistance to chemical corrosion

5). Safety storage and convenience usage.

Chemical resistance and weather resistance

| Salt spray test | GB/T1771-91,500 hours | The cross section of corrosion less than 2MM |

| Hot and damp resistance test | GB/T17740-79(89),1000 hours | Without air bubbles, loses the light slightly |

| Acid resistance | 10% CH3COOH, 240 hours | Without air bubbles, the surface without damage |

| Alkali resistance | 10% NaOH, 240 hours | Without air bubbles, the surface without damage |

| Heat resistance | 200degree,1 hour | The color change is lower than E=1.5 |

| Solvent resistance | MEK24 hours soaked in solvent-free | Without air bubbles, the surface without damage |

| Uvioresistant | QUV-313,500 hours |

Gloss higher than 80% lower than the Munsell color change level |

| Water tolerance of | 2 hours | No bubble, not falling, losing light |

| Test Item | Test Standard | Testing Results |

| SPecific Gravity | ≤1.7 | <1 |

| Thickness | 60~80цm | 77цm |

| Adhesive force | GB/T9286-1998 | 0 grade |

| Impact Resistance | GB/T1732-1993 | 50kg.cm no cracks nor stripping |

| Salt spray test | GB/T1771-1991 | 500H,no pulverization,gloss protection 80% |

| Winding Resistance | GB/T6742-1986 | 3mm no cracks nor stripping |

| Pencil Hardness | GB/T6739-1996 | 2H |

| UV Resistance | GB/T14522-1993 | 240h △E<1,gloss protection 80% |

| Flexibility | GB/T 6742-1986 | 2mm |

| Heat & Humidity Resistance | GB/T 1740-1979 | >500 Hours,film gloss slightly lose |

![]()