Reliable TGIC Pure Polyester Powder Coating RAL 1014 Ivory Color Eco Friendly

-

High Light

polyester powder coating paint

,uv resistant powder coating

-

Other NamesPowder Paint

-

ColorIvory

-

TypeThermosetting

-

FeatureEco-friendly

-

SurfaceRiver

-

Shelf Life12 Mos

-

Place of OriginUkraine

-

Brand NameTOPO

-

CertificationCE, ROHS, BV

-

Model NumberRAL1014

-

Minimum Order QuantityNegotiable

-

PriceNegotiable

-

Packaging DetailsTwo-ply PVC bag inside with carton box

-

Delivery Time7 days

-

Payment TermsL/C, T/T, Western Union, MoneyGram

-

Supply Ability400 T/Month

Reliable TGIC Pure Polyester Powder Coating RAL 1014 Ivory Color Eco Friendly

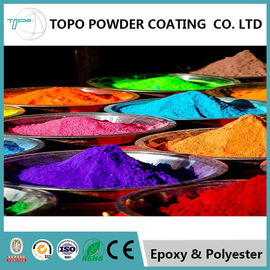

RAL1014 ivory color pure polyester TGIC powder coating sprayed by electrostatic spray gun

Powder coating is a type of coating that is applied as a free-flowing, dry powder. The coating is typically applied electrostatically and is then cured under heat to allow it to flow and form a "skin".

The powder may be a thermoplastic or a thermoset polymer. It is usually used to create a hard finish that is tougher than conventional paint.

Product series

Polyester powder coating can be categorized into two groups: with TGIC or without TGIC. It can produce the product of high gloss (above 80 percent), sub-gloss (20-50 percent), and the matt. The gloss can also be adjusted according to the client's instruction.

Application

Powder coating is mainly used for coating of metals, such as household appliances, aluminum extrusions, drum hardware, and automobile and bicycle parts. Newer technologies allow other materials, such as MDF (medium-density fibreboard), to be powder coated using different methods.

Specification

|

Inspection Item |

Test Standard or Method |

Test Indicator | |||

| Type A | Type B,C | ||||

| Impact resistance | ISO6272 | GB/T1732-1993 | 40cm | 50cm | |

| Cupping test | ISO1520 | GB/T9753-1988 | 5mm | 8mm | |

|

Adhesion (Planning grid method) |

ISO2409 | GB/T9286-1998 | Grade 0 | ||

| Crook | ISO1519 | GB/T6742-1986 | 3mm | 2mm | |

| Pencil hardness | ASTMD3363 | GB/T6739-1996 | 1H-2H | ||

| Salt test | ISO7253 | GB/T1771-1991 | > 500 hours | ||

| Heat test | ISO6270 | GB/T1740-1979 | > 1000 hours | ||

| Heat resistance | 100°C/24 hours (white) | Paul Light character (best) | |||

|

Remark |

Spraying gun: Corona Coating Thickness: Minimum – 35 microns |

||||

![]()