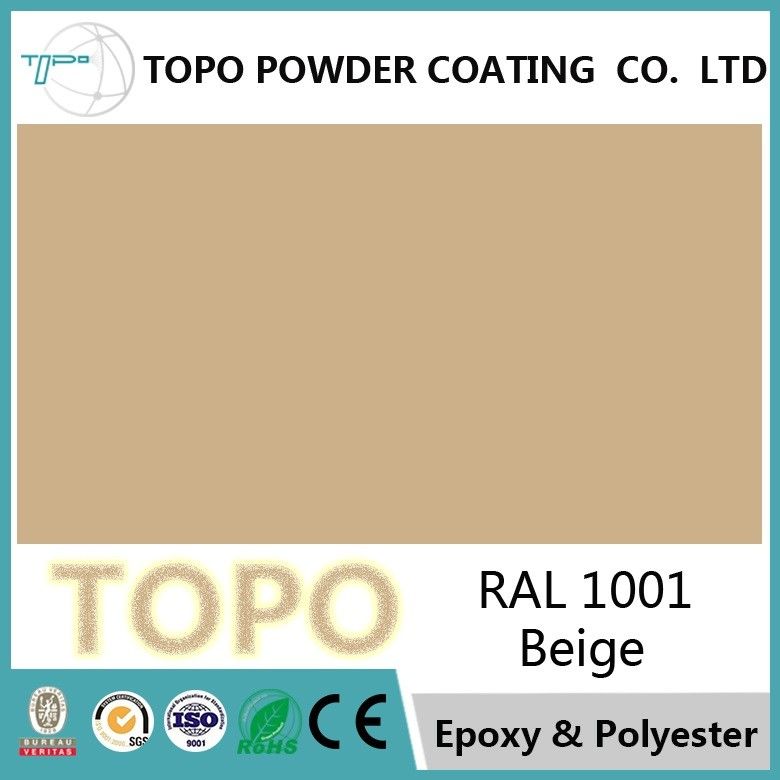

Outdoor Pure Polyester Powder Coating Anti Corrosive Ral 1001 Beige Color

-

High Light

polyester powder coating paint

,uv resistant powder coating

-

ColorBeige

-

SubstrateOutdoor Metal

-

ApplicationAutomotive Components

-

FeatureEnvironment Friendly

-

Impact Resistance50Kg/cm²

-

AdhesionEN ISO 2409 (2mm)

-

Place of OriginUkraine

-

Brand NameTOPO

-

CertificationCE, ROHS, BV

-

Model NumberRAL1001

-

Minimum Order QuantityNegotiable

-

PriceNegotiable

-

Packaging DetailsTwo-ply PVC bag inside with carton box

-

Delivery Time7 days

-

Payment TermsL/C, T/T, Western Union, MoneyGram

-

Supply Ability400 T/Month

Outdoor Pure Polyester Powder Coating Anti Corrosive Ral 1001 Beige Color

Ral1001 beige color Outdoor Anti-Corrosive Pure Polyester Powder Coating

This pure polyester powder coating is specifically designed for outdoor use.

Its outstanding gloss retention, durable color stability and mechanical properties make it best to be applied to building materials, electrical appliances, metal furnitures, automobile patrs ...

Compared with liquid paint, powder coating is more environmental friendly and economic. It can form a harder & thicker finish. Its excellent properties and attractive appearance of this product make it suitable for application to any other metal substrates.

Specifications

1)Good film tough,

2)Strong impact resistance,

3)light color, excellent constructio performance, good anti-corrosion ability

4)automotive car paint

Application

● Automotive Components ● Heaters

● Agricultural Equipment ● Wheels

● Architectural Cladding ● Lawn Mowers

● Cookers ● Garden Furniture

● Radiators ● Window Frames

Reference No’s

Polyster Gloss

Polyster Semi Gloss

Polyster Matt

Product Property:

The technical data provided below are typical for this product when applied as following:

Substrate: Metal panels

Substrate thickness (mm): 0.8

Film thickness (μm): 70-80

Typical values when tested have not necessarily been recently revised.

| Property | Standard | Result |

| Film appearance & color | No unevenness and no color difference | |

| Adhesion | EN ISO 2409 (2mm) | Cross-cut rating Gt0 (100% adhesion) |

| Impact resistance | EN ISO 6272/ASTM D2794 | 50Kg/cm² without film cracking |

| Cupping test | EN ISO 1520 | Indentation depth in excess of 5mm without film cracking |

| Flexibility | EN ISO 1519 | Cylindrical Mandrel bending test, passes 2 mm |

| Film hardness | EN ISO 2815 | 1H - 2H by Pencil Hardness Test |

| Drilling, milling and sawing | No flaking of coating | |

| Neutral salt spray resistance | ASTM B117 | No blistering or loss of adhesion after 1000 hours |

| Humidity resistance containing SO2 | EN ISO 3231 | No infiltration exceeding 1 mm on both sides of the scratch after 30 cycles. |

| Humidity resistance | EN ISO 270-2 | No infiltration exceeding 1 mm on both sides of the scratch after 1000 hours. |

| Acetic acid salt spray resistance | ISO 9227 | After 1000 hours testing - maximum 16mm infiltration over a scratch length of 10cm |

| Accelerated weathering | DIN EN ISO 11507 (UVB - 313) | Cycle: 4 hours at 50 C UV and 4 hours at 40 C condensation. No chalking, excellent gloss retention and color stability after 300 hours testing. |

| Accelerated weathering | DIN EN ISO 11507 (UVA - 340) | Cycle: 8 hours at 60 C UV and 4 hours at 45 C condensation. No chalking, excellent gloss retention and color stability after 1000 hours testing. |

| Natural weathering test | ISO 2810 | No chalking, excellent gloss retention and color stability after 12 months exposure (angle of 5° to South). |

![]()