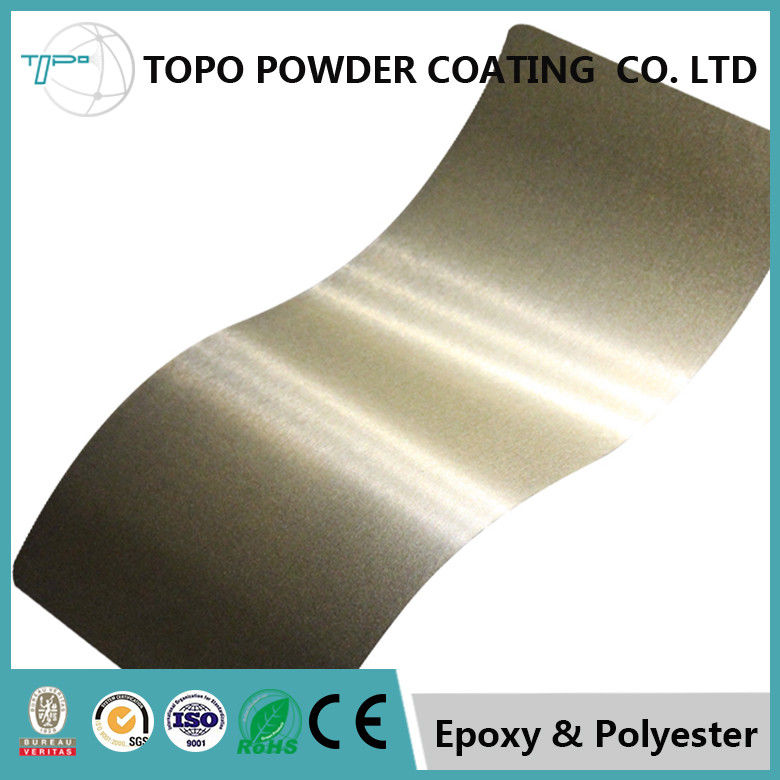

RAL 1005 Pipeline Powder Coating , CE Approval Cracky Surface Poly Powder Coating

-

High Light

polyurethane resin coating

,pu powder coating

-

ColorHoney Yellow

-

SubstratePipeline Corrosion

-

Package25kg

-

CAS No.N/A

-

SurfaceCracky

-

Main MaterialResin, Pigment

-

Place of OriginUkraine

-

Brand NameTOPO

-

CertificationCE, BV, ROHS

-

Model NumberPU-RAL1005

-

Minimum Order QuantityNegotiable

-

PriceNegotiable

-

Packaging DetailsTwo-ply PVC bag inside with carton box, net weight 20/25kg

-

Delivery Time7 days

-

Payment TermsL/C, T/T, Western Union, MoneyGram

-

Supply Ability400 T/Month

RAL 1005 Pipeline Powder Coating , CE Approval Cracky Surface Poly Powder Coating

RAL1005 honey yellow Polyurethane powder coating for Pipeline corrosion

Polyesters are typically somewhat softer and less abrasion resistant than their polyurethane counterparts. The additional crosslinker inherent in a polyurethane powder formulation is responsible for the added performance. Using the somewhat archaic pencil hardness test, polyesters clock in at H hardness whereas polyurethanes can achieve H to 5H depending upon the specific formulation. The higher hardness products typically sacrifice mechanical flexibility.

DESCRIPTION

1 “Polyurethane powder coating” is a series of polyurethane based powder coating formulated for exterior environment.

2 Offering excellent anti-corrosion and flexibility properties.

3 Excellent smoothness and high gloss

4 Available for a wide range of colors and gloss levels to suit different applications.

|

Test Item |

Test standard and Method |

Test index |

|

|

Impact resistance |

GB/T 1732 -1993 |

ISO6272 |

50kg/cm |

|

Adhension(cross-cut) |

GB/T 9286 - 1998 |

ISO2409 |

Class 0 |

|

Flexibility |

GB/T 6742-1986 |

ISO1519 |

2mm |

|

Pencil hardness |

GB/T 6739-1996 |

ISO2815 |

1H-2H |

|

Cupping test |

GB/T 9753-1988 |

ISO1520 |

6mm |

|

Salt spray resistance |

GB/T 1771-1991 |

ISO7253 |

>400 Hours |

|

Heat & humidity resistance |

GB/T 1740-1979 |

ISO6270 |

>500 Hours film gloss slightly lose |

|

Note: 1. Above test are using 0.30mm thickness degreased, rust removed cold rolling steel plate, film thickness is 60-80um.2. Film performance may slightly decrease with gloss decrease. |

|||

Powder Coating Features:

1. Non-polluted, environment friendly, high efficiency;

2. It can be recycle used and can save resource;

3. Good leveling property;

4. Excellent coating for angle margin;

5. Good adhesion, dispense with first coat;

6. Excellent weather resistance and wearing resistance;

7. Better than epoxy polyester on anti-yellowing

8. Good chemical and solvent resistance;

9. Good physical mechanical properties;

10. Wide range of coating color;

11. No by-products , without bubble and pinhole while curing.

![]()

![]()