RAL 1020 Pure Epoxy Coating , Excellent Chemical Resistant Powder Coating

-

High Light

epoxy resin powder coating

,epoxy powder coat paint

-

ColorOlive Yellow

-

Surface TypeMetal

-

Package25kg

-

TextureCrocodile

-

ApplicationAluminum Chair

-

GlossMiddle

-

Place of OriginUkraine

-

Brand NameTOPO

-

CertificationCE, BV, ROHS

-

Model NumberPE-RAL1020

-

Minimum Order QuantityNegotiable

-

PriceNegotiable

-

Packaging DetailsTwo-ply PVC bag inside with carton box, net weight 20/25kg

-

Delivery Time7 days

-

Payment TermsL/C, T/T, Western Union, MoneyGram

-

Supply Ability400 T/Month

RAL 1020 Pure Epoxy Coating , Excellent Chemical Resistant Powder Coating

RAL1020 olive yellow pure epoxy powder coating with Excellent corrosion resistance

Gives hard durable protective finishes with excellent adhesion and chemical resistance. Epoxy Powder Coating has good electrostatic charging properties and excellent transfer efficiency.

Recommended uses include general industrial components and applications requiring a good all round coating, such as household goods. When long term exterior durability or heat stability is essential a powder from our range of epoxy-polyesters and polyesters should be selected.

When flexibility, adhesion, toughness and corrosion resistance is required, epoxy powder coating is used extensively today. This coating is based on epoxy resins, which is manufactured in a way that enables the possibility of coating a high film build without any defect in the coating when cured.

Advantages:

Excellent corrosion resistance

Excellent chemical tolerance

High mechanical performance

Recommend for interior

Powder physical properties:

Specific gravity: 1.4-1.7 (for color and gloss vary)

Particle size distribution: 100% less than 100 microns (based on the special requirements of coating adjusted)

Fluidity: 120-140

Curing condition:

Type A - 200°C (work piece temperature), 15 minutes (flat or Matt)

Type B -180°C (work piece temperature), 15 minutes (highlight)

Type C -140°C (work piece temperature), 15 minutes (highlight)

Substrates and Pre-treatment

In order to obtain optimal anti-corrosion properties it is recommended to apply a chemical pretreatment prior to powder coating application

- Ferrous metals(cold rolled steel, cast iron ect.):Iron or Zinc phosphation

- Zinc surfaces(Galvanized steel, zinc alloy):Chromation or Zinc phophation

- Aluminum alloys:Chromatation

|

Test Item

|

Test Standard

|

Test Indicator | |||

| Type A | Type B,C | ||||

| Impact resistance | ISO6272 | GB/T1732-1993 | 40cm | 50cm | |

| Cupping test | ISO1520 | GB/T9753-1988 | 5mm | 8mm | |

| Adhesion(Planning grid method) | ISO2409 | GB/T9286-1998 | Grade 0 | ||

| Crook | ISO1519 | GB/T6742-1986 | 3mm | 2mm | |

| Pencil hardness | ASTMD3363 | GB/T6739-1996 | 1H-2H | ||

| Salt test | ISO7253 | GB/T1771-1991 | > 500 hours | ||

| Heat test | ISO6270 | GB/T1740-1979 | > 1000 hours | ||

| Heat resistance | 100°C/24 hours (white) | Paul Light character (best) | |||

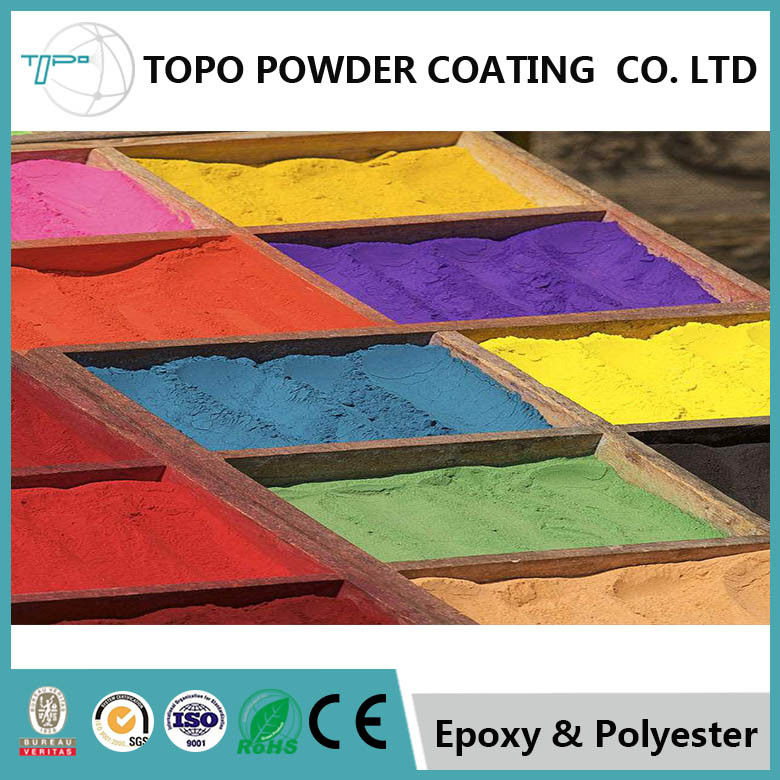

We offer powder coating capabilities that include a wide spectrum of colors, thickness, textures, softness, edge coverage, flexibilities, machinabilities, smoothness and temperature ranges.

Free samples are available.

![]()

![]()