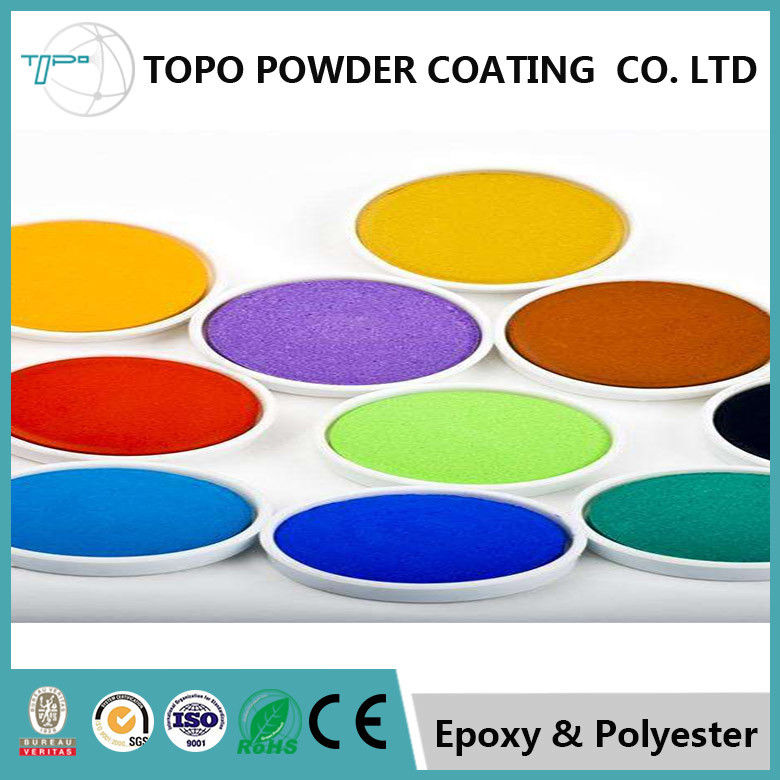

RAL 1006 Maize Yellow Pure Epoxy Powder Coating Reliable Resin Main Material

-

High Light

epoxy powder coat paint

,chemical resistant powder coating

-

ColorMaize Yellow

-

Surface TypeIron

-

Package25kg

-

Main MaterialResin

-

SurfaceNo Cracking Powder

-

ApplicationGas Pipe

-

Place of OriginUkraine

-

Brand NameTOPO

-

CertificationCE, BV, ROHS

-

Model NumberPE-RAL1006

-

Minimum Order QuantityNegotiable

-

PriceNegotiable

-

Packaging DetailsTwo-ply PVC bag inside with carton box, net weight 20/25kg

-

Delivery Time7 days

-

Payment TermsL/C, T/T, Western Union, MoneyGram

-

Supply Ability400 T/Month

RAL 1006 Maize Yellow Pure Epoxy Powder Coating Reliable Resin Main Material

RAL1006 maize yellow pure powder coating paint epoxy resins solid powder coating

Because of the large number of available epoxy resins each resin’s ability to react with a wide variety of curing agents, nearly and combination of desired physical properties can be obtained. With proper selection of components (raw materials), epoxy-based (pure epoxies and hybrids) coating powders can be formulated to be FDA compliant for food contact applications. The primary limitations of epoxy-based coatings are their poor weather ability.

Powder Specification

|

Inspection Item |

Test Standard or Method |

Test Indicator | |||

| Type A | Type B,C | ||||

| Impact resistance | ISO6272 | GB/T1732-1993 | 40cm | 50cm | |

| Cupping test | ISO1520 | GB/T9753-1988 | 5mm | 8mm | |

| Adhesion(Planning grid method) | ISO2409 | GB/T9286-1998 | Grade 0 | ||

| Crook | ISO1519 | GB/T6742-1986 | 3mm | 2mm | |

| Pencil hardness | ASTMD3363 | GB/T6739-1996 | 1H-2H | ||

| Salt test | ISO7253 | GB/T1771-1991 | > 500 hours | ||

| Heat test | ISO6270 | GB/T1740-1979 | > 1000 hours | ||

| Heat resistance | 100°C/24 hours (white) | Paul Light character (best) | |||

Coating Specification

|

Testing Items |

Technical Indicators |

Test Standard |

|

Appearance |

smooth,uniform color, no bubble , no cracking and sinkhole, allow light crack |

visual |

|

24h or 48h adhesion |

1~2 |

SY/T 0315-2005 |

|

24h or 48h cathodicdisbonding resistance(mm) |

≤6 |

SY/T 0315-2005 |

|

cathodicdisbonding resistance 28d(mm) |

≤ 8 |

SY/T 0315-2005 |

|

Porosity of bottom section |

1~4 |

SY/T 0315-2005 |

|

Porosity of underlying surface |

1~4 |

SY/T 0315-2005 |

|

2° bending resistant(0°or -30°) common level |

No cracking |

Q/CNPC38-2002 appendix D |

|

1.5°bending resistant(0°or-30°)Intensify Level |

No cracking |

Q/CNPC38-2002 appendixD |

|

10J Impact(common level) |

No pinehole |

Q/CNPC 38-2002 appendix E |

|

15J Impact Intensify Level |

No pinehole |

Q/CNPC 38-2002 appendix E |

|

scratchresistant, 30Kg, common level |

Scratch depth≤350μm No leaking point |

Q/CNPC 38-2002 appendix F |

|

scratchresistant,50Kg, Intensify Level |

Scratch depth≤500μm No leaking point |

Q/CNPC 38-2002 appendix F |

![]()